Structural characteristics

KWP non-clogging centrifugal pump is the introduction of German KSB technology, horizontal, single-stage, high-efficiency energy-saving anti-blocking pump. The rear disassembled structure can remove the rotor components without removing the inlet and outlet pipelines, and has four impeller forms of K, N, O and F to meet the transportation of different media.

Structural characteristics

KWP non-clogging centrifugal pump is the introduction of German KSB technology, horizontal, single-stage, high-efficiency energy-saving anti-blocking pump. The rear disassembled structure can remove the rotor components without removing the inlet and outlet pipelines, and has four impeller forms of K, N, O and F to meet the transportation of different media.

Applicable working conditions

KWP pump can transport sewage, seawater, brine, sludge and other media containing long fibers, straw, oily, viscous liquid and coarse materials in liquids. It is widely used in sewage treatment, paper mills, breweries, food processing, biogas projects. , kitchen processing, fish industry, aquaculture and other industries.

Performance range

Discharge range: 40 ~ 500mm

Flow range: 10~3100m3/h

Head range: 3 ~ 90m

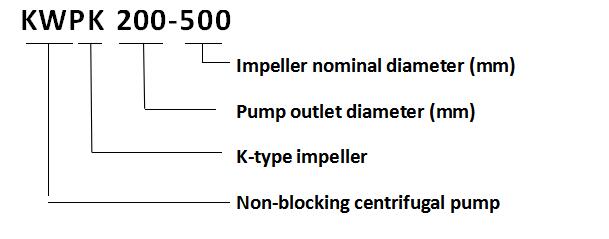

Model meaning

Impeller description:

K-type impeller Closed non-blocking impeller. It is suitable for transporting clean water, sewage, and solids-containing media. The medium should not contain solids that are particularly easy to adhere and easy to entangle (such as extra long fibers or coarse rubber particles).

N-type impeller Closed multi-blade impeller. It is suitable for conveying medium containing light solid suspended matter, such as clean water, mechanically treated sewage, sorting water, pulp, sugar juice, etc., which is the preferred structure of the pulp pump.

O-type impeller Open impeller. The scope of application is basically the same as that of the N-type impeller, but the medium in the medium may contain gas.

F-type impeller Free-flow impeller. It is suitable for conveying media containing gas or coarse materials. It is also suitable for conveying solid media which is easy to adhere and easy to wrap, such as extra long fiber, kitchen waste, weed, heavy fertilizer, plastic paper, rubber, rubber and so on.

KWP series non-blocking centrifugal pump basic parameters

| KWP Pump Code | Flow Q(m3/h) | Head H(m) | Rotating speed n(r/min) | Efficiency η(%) | NPSHr(m) | Discharge diameter(mm) | Suction diameter(mm) |

| KWPk40-250 | 15~50 | 25~90 | 2900 | 40~55 | 2.0~4.0 | 40 | 65 |

| KWPk40-250 | 10~35 | 9~23 | 1450 | 42~53 | 1.0~3.0 | 40 | 65 |

| KWPk40-250 | 5.0~15 | 3~11 | 980 | 30~45 | 0.5~4.2 | 40 | 65 |

| KWPk50-200 | 20~80 | 22~60 | 2900 | 52~68 | 0.5~4.8 | 50 | 65 |

| KWPk50-200 | 22~45 | 5~15 | 1450 | 55~63 | 0.5~2.0 | 50 | 65 |

| KWPk50-200 | 13~28 | 2.6~6.5 | 970 | 45~67 | 0.3~1.8 | 50 | 65 |

| KWPk65-200 | 45~120 | 16~60 | 2900 | 55~73 | 2.0~4.5 | 65 | 80 |

| KWPk65-200 | 20~45 | 8~18 | 1450 | 50~53 | 1.0~3.2 | 65 | 80 |

| KWPk65-200 | 17~40 | 2~6.7 | 980 | 40~61 | 0.4~1.2 | 65 | 80 |

| KWPk65-315 | 50~130 | 43~85 | 2900 | 50~67 | 3.5~5.7 | 65 | 80 |

| KWPk65-315 | 33~110 | 16~40 | 1450 | 51~66 | 1.0~4.1 | 65 | 80 |

| KWPk65-400 | 40~130 | 22~60 | 1450 | 52~63 | 0.5~2.0 | 65 | 80 |

| KWPk65-400 | 25~80 | 12~27 | 960 | 50~62 | 0.5~2.0 | 65 | 80 |

| KWPk80-315 | 40~128 | 17~35 | 1450 | 55~72 | 0.5~2.0 | 80 | 100 |

| KWPk80-315 | 25~80 | 8~17 | 960 | 53~69 | 1.0~3.0 | 80 | 100 |

| KWPk100-250 | 80~200 | 22~60 | 2900 | 51~75 | 1.0~4.0 | 80 | 100 |

| KWPk100-250 | 55~150 | 6~21 | 1450 | 61~77 | 1.0~2.3 | 80 | 100 |

| KWPk100-315 | 52~150 | 16~38 | 1450 | 53~74 | 2.0~3.5 | 100 | 125 |

| KWPk100-315 | 24~110 | 6~16 | 960 | 50~69 | 0.5~1.0 | 100 | 125 |

| KWPk100-400 | 55~172 | 16~60 | 1450 | 51~72 | 2.0~3.5 | 100 | 125 |

| KWPk100-400 | 50~130 | 11~27 | 960 | 52~69 | 1.1~2.1 | 100 | 125 |

| KWPk125-315 | 120~300 | 10~35 | 1450 | 61~78 | 1.5~4.5 | 125 | 150 |

| KWPk125-315 | 100~220 | 5~13 | 960 | 65~77 | 1.0~2.0 | 125 | 150 |

| KWPk125-400 | 190~380 | 20~58 | 1450 | 65~75 | 2.5~3.0 | 125 | 150 |

| KWPk125-400 | 110~240 | 11~22 | 960 | 60~74 | 0.5~2.0 | 125 | 150 |

| KWPk125-500 | 170~370 | 35~88 | 1450 | 55~65 | 0.5~5.5 | 125 | 150 |

| KWPk125-500 | 70~250 | 18~37 | 960 | 50~72 | 1.5~2.5 | 125 | 150 |

| KWPk150-315 | 180~410 | 12~30 | 1450 | 71~76 | 1.5~2.8 | 150 | 150 |

| KWPk150-315 | 100~260 | 4.5~13 | 960 | 51~72 | 1.0~1.6 | 150 | 150 |

| KWPk150-500 | 210~460 | 32~98 | 1450 | 60~74 | 2.5~4.2 | 150 | 150 |

| KWPk150-500 | 180~310 | 18~37 | 960 | 60~73 | 0.5~1.9 | 150 | 150 |

| KWPk150-500 | 110~265 | 4.5~22 | 725 | 65~75 | 1.3~2.0 | 150 | 150 |

| KWPk200-400 | 300~590 | 23~55 | 1450 | 68~85 | 2.0~4.0 | 200 | 200 |

| KWPk200-400 | 180~400 | 12~24 | 960 | 65~86 | 0.5~2.1 | 200 | 200 |

| KWPk200-400 | 145~280 | 6~13 | 725 | 72~85 | 0.5~1.6 | 200 | 200 |

| KWPk200-500 | 320~725 | 45~90 | 1450 | 62~82 | 1.5~5.1 | 200 | 200 |

| KWPk200-500 | 400~650 | 18~35 | 960 | 75~83 | 0.5~3.1 | 200 | 200 |

| KWPk200-500 | 310~550 | 9~20 | 725 | 75~82 | 1.0~2.2 | 200 | 200 |

| KWPk250-500 | 600~1220 | 32~85 | 1450 | 71~80 | 1.5~7.5 | 250 | 250 |

| KWPk250-500 | 450~820 | 18~36 | 960 | 76~83 | 0.5~3.5 | 250 | 250 |

| KWPk300-500 | 720~1600 | 40~78 | 1450 | 68~82 | 4.1~9.5 | 300 | 300 |

| KWPk300-500 | 850~1200 | 18~32 | 960 | 77~84 | 4.1~6.4 | 300 | 300 |

| KWPk300-500 | 450~830 | 5.2~19 | 725 | 65~83 | 1.0~5.0 | 300 | 300 |

| KWPk350-500 | 1000~2450 | 35~70 | 1450 | 60~89 | 4.0~7.0 | 350 | 350 |

| KWPk350-500 | 1200~1850 | 16~30 | 960 | 77~88 | 5.0~6.9 | 350 | 350 |

| KWPk350-500 | 800~1520 | 6~15 | 725 | 70~88 | 3.0~7.0 | 350 | 350 |

| KWPk350-630 | 1200~2550 | 21~56 | 960 | 75~84 | 2.0~6.0 | 350 | 350 |

| KWPk350-630 | 900~1890 | 14~27 | 725 | 75~83 | 2.0~6.2 | 350 | 350 |

| KWPk350-630 | 1200~2550 | 21~56 | 725 | 80~83 | 2.8~6.5 | 350 | 350 |

| KWPk400-500 | 2000~2600 | 14~28 | 960 | 80~87 | 2.0~7.3 | 400 | 400 |

| KWPk400-500 | 1400~2240 | 8.5~14 | 725 | 75~86 | 4.0~8.0 | 400 | 400 |

| KWPk500-630 | 2800~3600 | 22~40 | 960 | 79~85 | 2.0~6.7 | 500 | 500 |

| KWPk500-630 | 2000~2800 | 14~22 | 725 | 75~85 | 3.1~6.0 | 500 | 500 |